Fast Cutting High Precision CNC Oscillating Knife Cutter Cloth Fabric Cutting Machine for Garment Sofa Toys Umbrella Industry.

Jinan Kang Jia CNC Equipment Co., Ltd.- Voltage:220V

- Power Source:Electric

- Automatic Grade:Automatic

- Warranty:1 year

- Certification:CE, ISO

- Cutting Thickness:0.1-18mm(Depend on Material)

Base Info

- Model NO.:KJZD-1625

- Mechanical Precisio:<0.01mm

- Supported Software:Coreldraw, Autocad

- Work Plate:2500mm*1600mm

- Machine Size:3260*2120*1315mm

- Cutting Speed:0-1500mm,S

- Transmission Interface:Cable Transmission

- Supported Format:Pxf Plt

- Fan Power:9kw

- Material Fixed Mode:VAC-Sorb

- Driving Mode:Racking Drive

- Support File Forma:Dxf, Plt

- Transport Package:Packed in Wooden Cases

- Specification:KJ-1625

- Trademark:kangjia

- Origin:China

- HS Code:8453100000

- Production Capacity:100 Sets , Month

Description

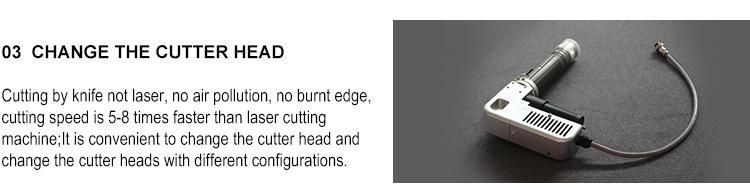

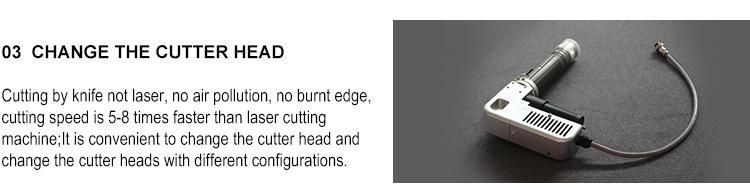

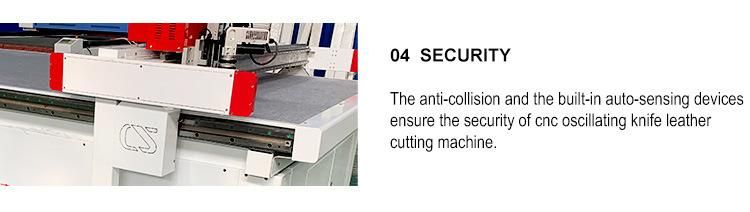

Multifunctional heads optonalVibration knife (oscillatory knife) Circular knife (round knife / rotary knife) Oblique knife (V-cut) Marking pen Punching roller (round punching/v-punching/optional) Milling knife Drag knife Pneumatic knife Projector and camera optional Safety device Using infrared sensors, mechanical safty device, Intelligent anti-collision device responsive, safe and reliable. Material feeding type Auto feeding or manual feeding Material fixed type Vac-sorb (vacuum absorption), suction fan power: 2.2kw / 7.5kw / 9kw Translational velocity 800-1500mm/s Cutting speed Max. 1500mm/s (according to different cutting materials) Cutting thickess ≤60mm (according to different cutting materials) Cutting material Fabric, all kinds of clothing flexible material, Sponge leather, PVC, soft glass, Silicon, rubber, cardboard etc. Repated accuracy ≤0.1mm Cutting type Mechanical vibration physical cutting Transmission / driving system Motor brand Panasonic, YASKAWA, Fuji, Delta Transmission type / Guide rail Digital servo motor, linear guide, synchronous belt, rack/spline, ball screw Instruction system HP-GL compatible format Control system LCD touch screem ( custom made) Voltage 110V/220V / 380V±10%; 50HZ, 60HZ Other configuration Germany imported conveyor belt, vacuum table, Taiwan Hiwin rail, vacuum pump

Product Advantage:

1. Environmental protection, no smoke & no smell.

2. High Efficiency, the cutting speed can reach max. 1500m/s (per material), save time and worker cost.

3. Beautiful appearance, no yellow edge & rough selvedge after cutting.

4. Multifunctional cutting, support abnormity cutting, apply for many industries.

5. Wide range of applications: garment industry, automotive interior (floor mat, seat cover etc.), advertise industry, furniture industry (sofa), leather industry, clothing industry etc.

B. You can come to our factory for training. We will offer professional guide. Direct and effective face-to-face training. Here we have assembled equipments all sorts of tools and testing facility,we will also provide accomadation during training period. Training Time: 1-10 working days.

Packaging & Shipping:

About us:

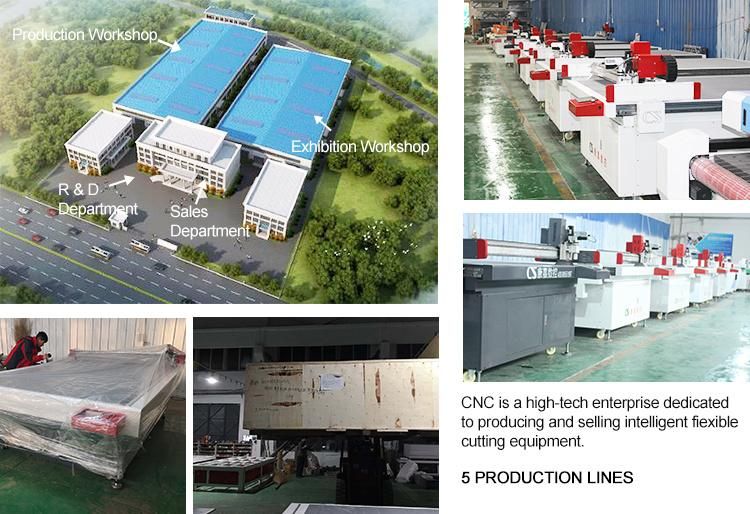

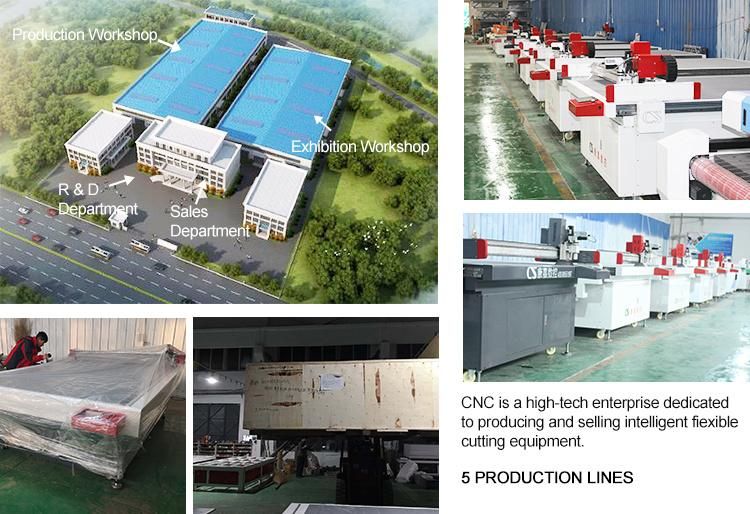

Our company has focused on oscillating knife cutting machine for over 5 years, It is a comprehensive service company specializing in the production, sales and technical service of knife cutting machine. Our factory covers 10000 square meters, with 150 staffs in total. The production capacity is about 100 unit / month. Warmly welcome to visit our factory.

With the repaid development of global economic, man's environmental awareness become more and more strength. In this case, the oscillation knife is came into the market and approved by many flexible materials' industries.

Exhibition:

Certificate:

RFQ

Q: 1. How can I choose a suitable Knife cutting machine?

A: Please provide us some info, then we can recommend you the suitable machine:

1)What materials are going to cut? Are they rolled or not? Breathable or not?

2)What's the largest size of original materials?

3)What's the thickness of materials?

4)Excepting for cutting, do you need more functions, like drawing, punching holes, scanning, feeding, CCD camera, etc.?

Q: 2. Can you design a machine for me depending on my requirements?

A: Of course, we will give our professional suggest and discuss details with you for the machine which matches all the requests with best cost performance.

Q: 3. What should I do if the machine has any problem in future?

A: We supply online/phone technical support and door to door service. Anything confuse or not goes well, pls contact us in the first time.

Q: 4. What's the warranty policy?

A:Standard warranty is 12 months upon delivery.

Main parts are free of charge(except consumable parts) when problems happened because of quality problem during this period.

Problems caused by wrong operate will also well-solved, but not for free.

We also supply life long after-sales service. No matter when, you can count on our best service for your machine.

Q: 5. If I don't know this machine before, how can I operate it?

A: We supply face to face training and provide operating video, user manual, and telephone calls to help.

It's easy to learn, one inexperience people can learn it within one day.

Product Advantage:

1. Environmental protection, no smoke & no smell.

2. High Efficiency, the cutting speed can reach max. 1500m/s (per material), save time and worker cost.

3. Beautiful appearance, no yellow edge & rough selvedge after cutting.

4. Multifunctional cutting, support abnormity cutting, apply for many industries.

5. Wide range of applications: garment industry, automotive interior (floor mat, seat cover etc.), advertise industry, furniture industry (sofa), leather industry, clothing industry etc.

Training to install (2options):

A. We will supply the machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, fax, telephone/MSN/ICQ and so on, when you meet some problems of installation, using or adjusting.B. You can come to our factory for training. We will offer professional guide. Direct and effective face-to-face training. Here we have assembled equipments all sorts of tools and testing facility,we will also provide accomadation during training period. Training Time: 1-10 working days.

Packaging & Shipping:

About us:

Our company has focused on oscillating knife cutting machine for over 5 years, It is a comprehensive service company specializing in the production, sales and technical service of knife cutting machine. Our factory covers 10000 square meters, with 150 staffs in total. The production capacity is about 100 unit / month. Warmly welcome to visit our factory.

With the repaid development of global economic, man's environmental awareness become more and more strength. In this case, the oscillation knife is came into the market and approved by many flexible materials' industries.

Exhibition:

Certificate:

RFQ

Q: 1. How can I choose a suitable Knife cutting machine?

A: Please provide us some info, then we can recommend you the suitable machine:

1)What materials are going to cut? Are they rolled or not? Breathable or not?

2)What's the largest size of original materials?

3)What's the thickness of materials?

4)Excepting for cutting, do you need more functions, like drawing, punching holes, scanning, feeding, CCD camera, etc.?

Q: 2. Can you design a machine for me depending on my requirements?

A: Of course, we will give our professional suggest and discuss details with you for the machine which matches all the requests with best cost performance.

Q: 3. What should I do if the machine has any problem in future?

A: We supply online/phone technical support and door to door service. Anything confuse or not goes well, pls contact us in the first time.

Q: 4. What's the warranty policy?

A:Standard warranty is 12 months upon delivery.

Main parts are free of charge(except consumable parts) when problems happened because of quality problem during this period.

Problems caused by wrong operate will also well-solved, but not for free.

We also supply life long after-sales service. No matter when, you can count on our best service for your machine.

Q: 5. If I don't know this machine before, how can I operate it?

A: We supply face to face training and provide operating video, user manual, and telephone calls to help.

It's easy to learn, one inexperience people can learn it within one day.